Thanks to innovations in the roofing industry, decramastic tiles have been superseded by today’s pressed steel tiles. And with a different process, comes a superior product. In this blog, we delve further into the history of decramastic tiles and how they differ from what’s in use now.

The History Of Decramastic Tiles

The idea of the chip coating tiles came from an Englishman, Ben Booth, who developed a process for coating steel sheet with bitumen onto which sand or grit was applied to prevent the sheets sticking together when stacked. It has been suggested that this was also to reduce glare as a form of camouflage during the wartime period around 1940. Metal tiles were made using this basic coating process from the late 1950’s onward.

Historic decramastic tiles

However these processes changed in 1976 when AHI Roofing initiated a major research program with the then modern technology of acrylics. By 1980 galvanized steel was used, the new acrylic based product had replaced the old bituminous emulsion and these metal tiles were marketed under the brand Decrabond and New Harveytile. Decramastic roofing tiles were widely used in New Zealand during the 70’s and 80’s.

A Different Process = A Different Product

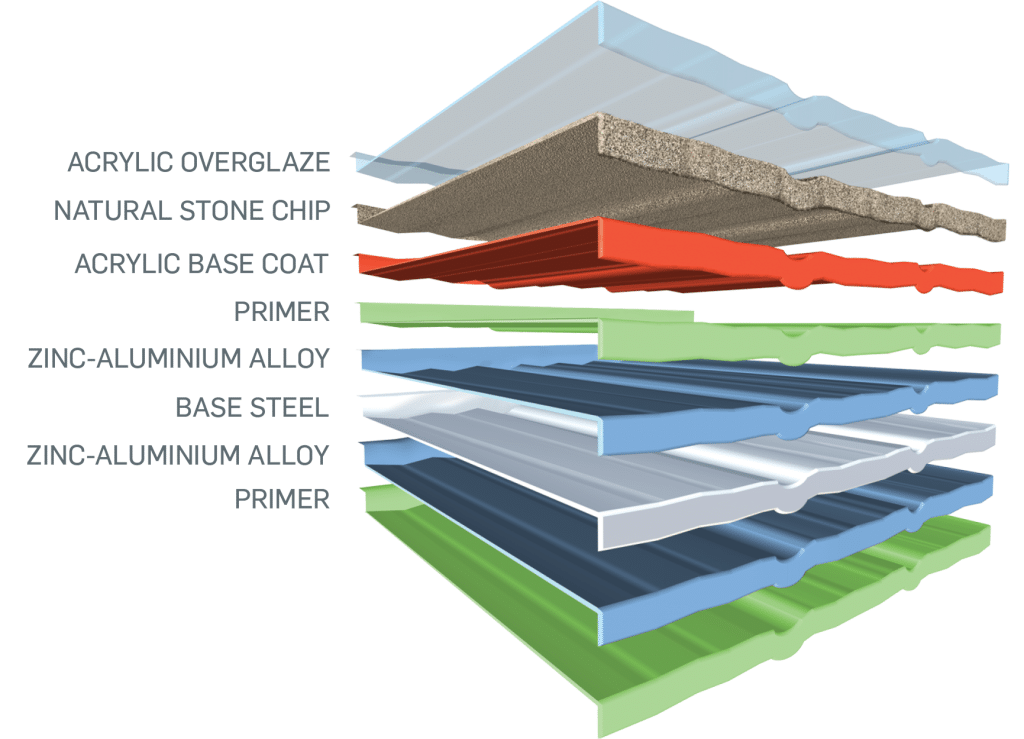

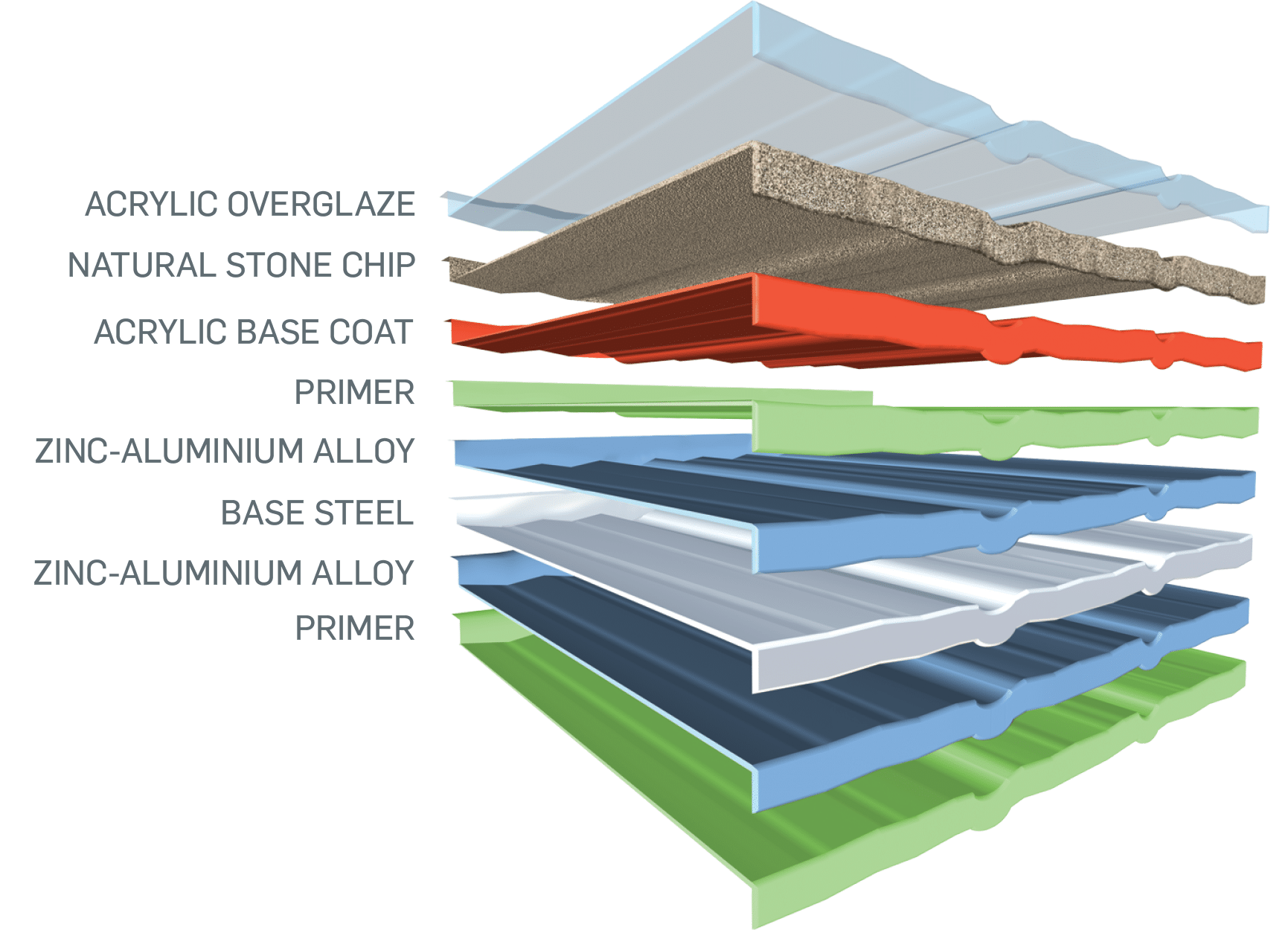

In today’s pressed metal tiles, a zinc-aluminium alloy coated steel combines the corrosion protection of aluminium with the sacrificial protection of zinc to create an alloy that’s ideal for roofing and cladding in Australia’s demanding environment – replaces the galvanized steel. A new and improved acrylic base coat is applied, which allows for the stone granules to set deeper into the base coat. A layer of glaze is applied on top of stone granules, which helps bind the steel, base coat and stone granules together. These tiles placed on racks and cured in an oven to bake the stones on and ensure a strong resilient adhesion.

A breakdown of today’s pressed metal tiles

New Product = New Styles

For many people when they think of Decramastic tiles, they imagine a scallop-shaped metal tile roof coated with stone chip. While this style is still around today, there are many more available to consumers and most pressed metal tile manufacturers offer both a textured (stone coated) and a satin (smooth, painted) finish. Gerard offers a range of profiles, Stratos, Rockport & Milano. This means that whatever look you are wanting can be achieved by using pressed steel tiles, see our full range below: